Raster engraving, on the other hand, works perfectly for art-works that come with bolder appearance. Vector engraving is therefore perfect for small items like jewelry and other decorative items. Vector engraving is used where finer details are required which is not possible with raster engraving. When it comes to appearance, vector engraving looks much finer than raster engraving because raster engraving is just one line thick. Vector engraving is perfect for flat materials and since it engraves in a continuous manner, the vector engraving is less time consuming than raster engraving. If you use a low power setting, you will get an engraved image but if you use a high-power setting, you will get a laser cut. Vector engraving works the same as laser cutting except for the power settings. The axles move slowly but simultaneously to achieve a smooth engraving.

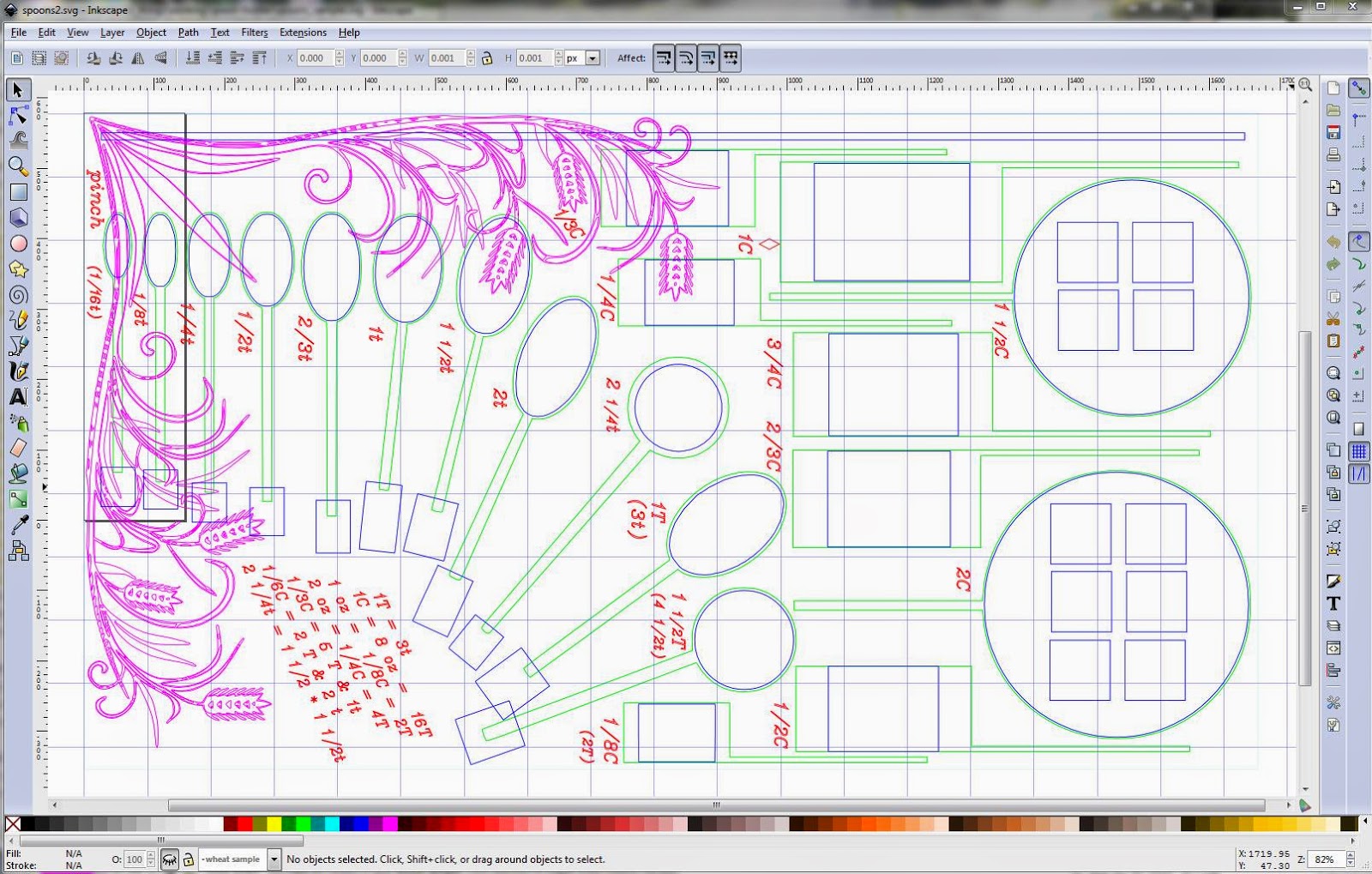

The laser traces the image vector by vector and engraves it on the material. Once the file is imported from a graphics software, the outline is marked for vector engraving. The laser keeps following the instructions given by the computer and engraves the piece smoothly.

#Raster meaning laser cutter series#

Vector image engraving is also known as “Scoring.” The CNC controller uses the series of linear X-axis and Y-axis locations and directions for the laser to point based on the image generated by the computer. Each path is rooted with a mathematical formula that determines the shape, as well as the fill and border colors. Vector images are made of thin lines and curves which are known as paths. Since it engraves one pixel at a time, raster engraving is somewhat slow. The PPI (Pulses Per Inch) also plays a crucial role as it controls the density of the laser points. The speed of the X axle (the axle where the laser-head is attached) is always higher than the Y-axle. It is a bi-directional process in which engraving is done in an alternating manner in both directions.ĭuring the line by line engraving process, both axles run with different speed.

0 kommentar(er)

0 kommentar(er)